Get Your Free Quote…!

SEVITSIL®

SEVITSIL®

Catalogue Request Form…!

Silicone Rubber in Electric Vehicles Application

Advantages over choosing silicone rubber

- 1Flow, wetting, adhesion and cure properties that can help speed and simplify processing

- 2Reliable performance under harsh conditions

Applications

- 1Electrical wiring systems

- 2Temperature sensors

- 3Engine/motor cabling

- 4Battery cables

- 5Airbags

- 6Door locking systems

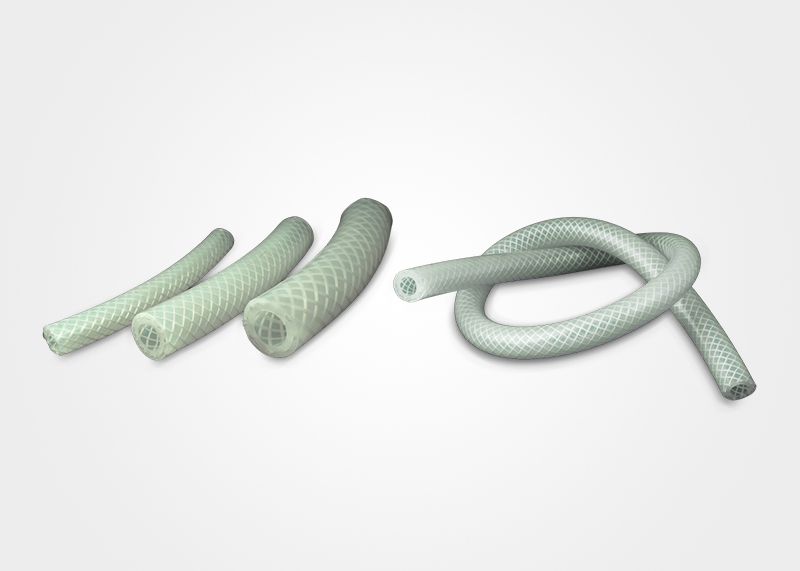

- 7Rainwater drain hoses

- 8Door and window seals

- 9Windshield washer systems

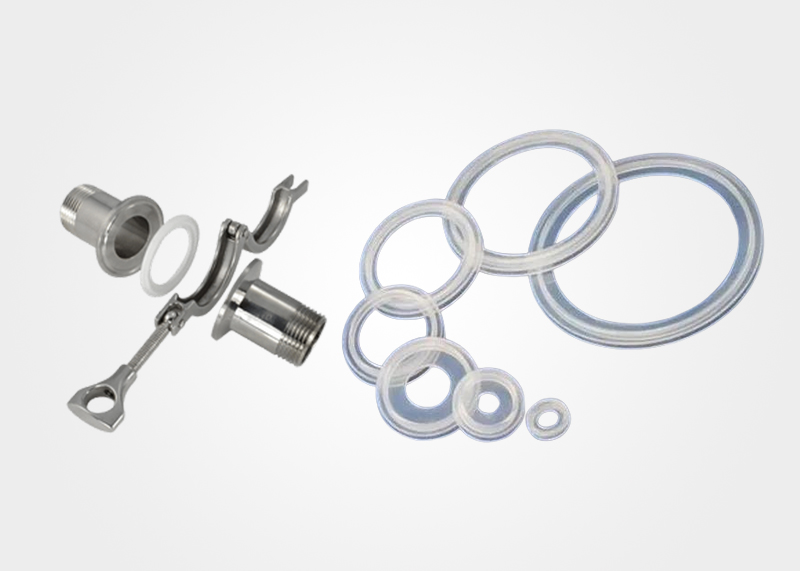

- 10Spark plug connector gaskets

Inquiry Form

Related Products

FAQ

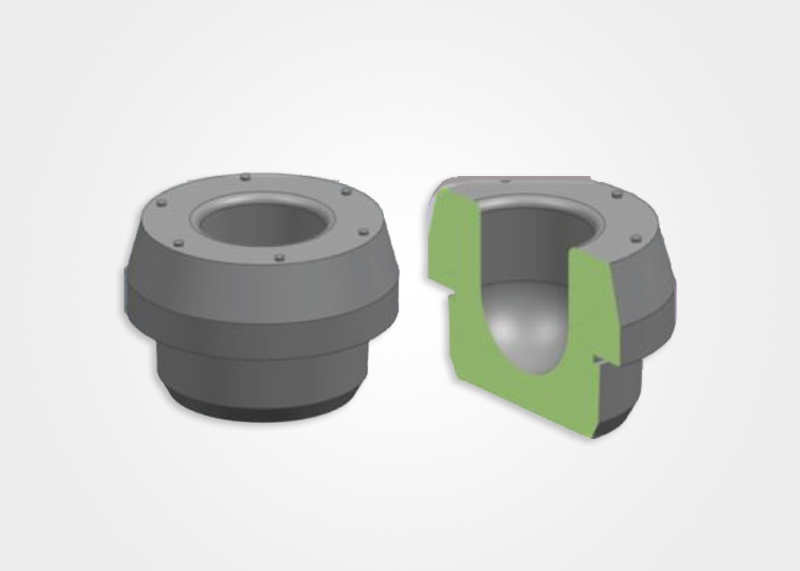

Silicone rubber is an elastomer composed of silicone(present in silica) together with carbon,oxygen and hydrogen.

IN 1930, JAMES FRANKLIN HYDE RAN THE FIRST RESEARCH TO PRODUCE COMMERCIAL SILICONES.

Silicon is an element which is present in silica (sand) while silicone rubber is manufactured by extracting silicon from silica and passing it through hydrocarbons. It's then mixed with the other chemicals to create silicone.

A silicone or polysiloxane is a polymer made up of siloxane (−R2Si−O−SiR2−, where R = organic group).

.png)